What we do

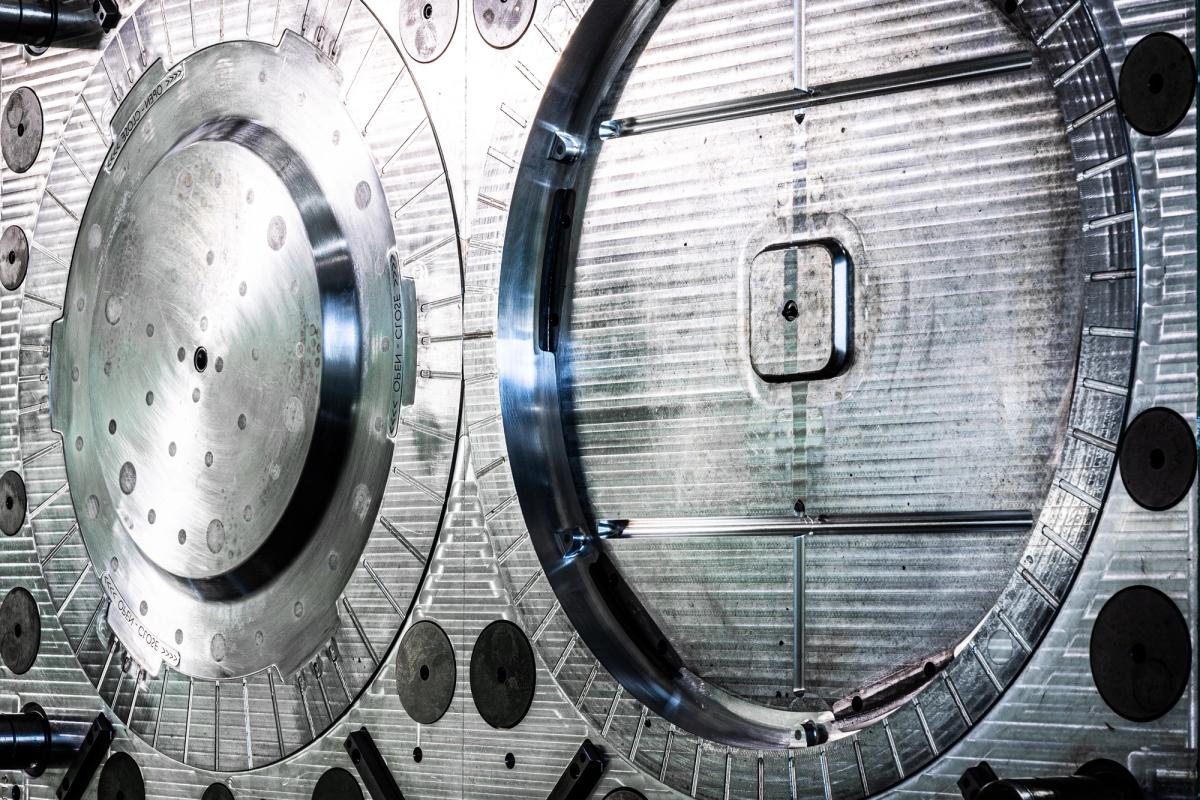

Through more than 50 years in the business we have gained extensive and marked leading experience with delivering engineering services and solutions related to injection moulds for use in production of technical plastic components.

When the moulds are ready for production, we are offering serial production of technical plastic components. Production is executed in our top modern factory in Leksvik, just outside Trondheim in the middle of Norway.

We offer assembly, fully automized and semi automized, depending on which solution that serves the product and the customer in a best possible way.

Competence and process

Our highly qualified project managers and engineering team may be responsible for the whole value chain, from conseptual product design to complete turnkey moulds ready for serial production of moulded plastic parts.

Using top modern software for advanced analysis and fully integrated 3D design, we secure the most cost effective and technically optimzed solutions according to customer specifications.

The moulds are produces at carefully chosen partner factories in Europe and Asia. This secures that all quality requirements, toleranses and sycle times are fullfilled and that the moulds work as they should before put into produciton in our Leksvik factory.

Our combined competense and carefully established processes, secures the most cost-effective production in the marked, and the best overall solution for our customers.

What we deliver

We deliver products to different markeds and with variating requirements. We focus understanding how the products should function during use, to be able to optimize the products specifications:

Design and function Rigidity, siziness and impact strength Envirolmental effects (chemicals, temperatures, preassure etc) Weight Lifetime Price Recycling/sustainability/reusability

We may assist you throug the whole product development process, from idea to finished product.